SHAPED BY

EXPERIENCE

ABOUT US

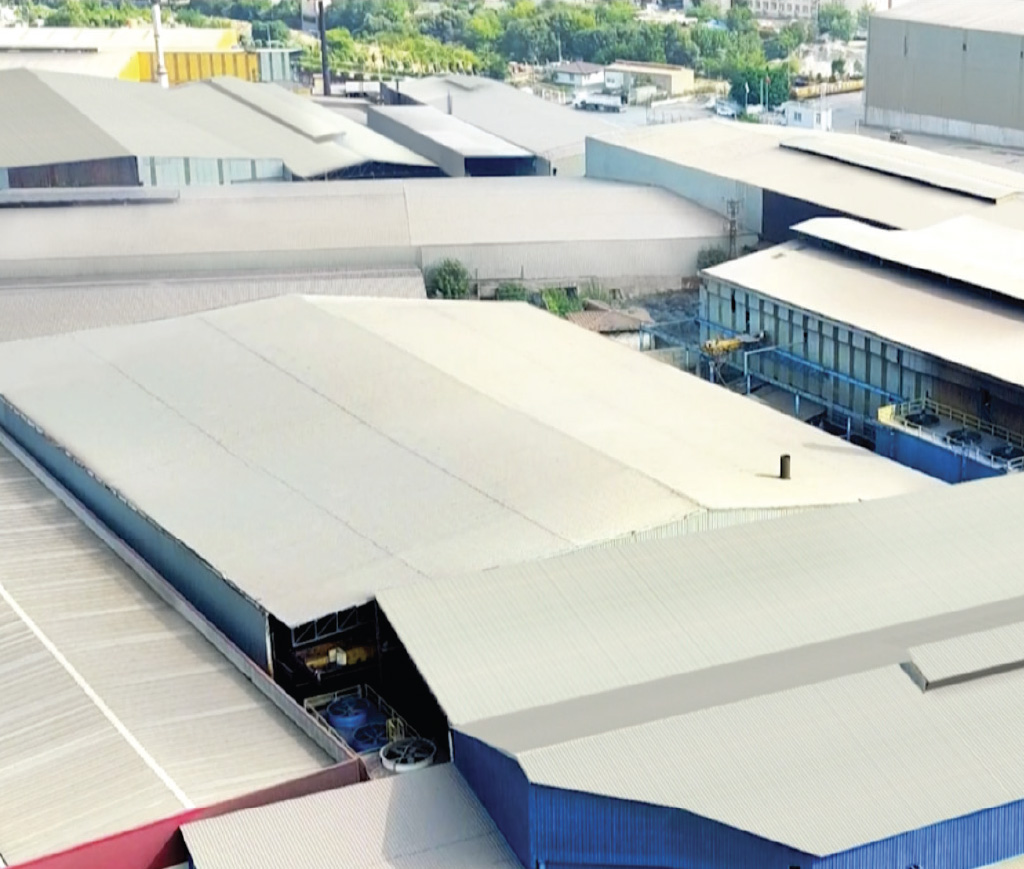

Kendirliler, which began its commercial life in 2003 in the Payas Organized Industrial Zone, has now become a stable and leading company in the sector with a registered capital of 12 million, assets totaling 85 million, and an annual turnover exceeding 250 million. Our company, which is among the leading establishments in the industry, is also ranked among the top 500 industrial firms in Turkey.

By using the latest technological systems, Kendirliler has continuously improved its production capacity, number of employees, sales figures, investment amounts, and corporate structure year after year. The company has an annual production capacity of approximately 500,000 tons/year.

Photo From Us

KENDİRLİLER HADDECİLİK

Facilities

There is Strength in its Material, Confidence in its Service!

Makes the Difference Live with the Combination of Technology and Innovation!